Challenge: Bioreactors and other expression systems used to produce biopharmaceuticals might reasonably be compared to a brewer’s vat where various components are cooked slowly in a tank to manufacture a product. Temperature, oxygenation and the ‘recipe’ combine to let the cells – in case of brewing, yeast (or in the case of biopharmaceutical a variety of bacteria and other cells), make the product. The uptake of amino acids into a growing protein is a vitally important parameter as it shows how efficient the design of the experiment has been, and how effective the production of the biopharmaceutical can be overall. However, the current technologies used for amino acid analysis are not ideal for this process and new approaches need to be taken.

Rationale: Amino acids analysis is presently mostly performed on various types of high performance liquid chromatography (HPLC or MicroHPLC). This is a fairly complex and oldfashioned technique that involves labelling or ‘derivitising’ the amino acids, a seven-stage process that takes up to 30 minutes,

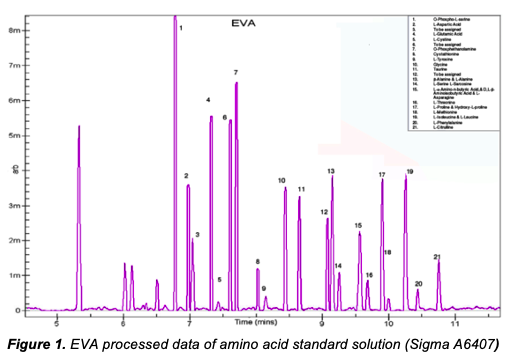

deltaDOT Solution: deltaDOT’s core technology of Label Free Intrinsic Imaging, (LFII® ) is generally applied to the analysis of analytes that absorb UV light at sample specific wavelengths. Things that do not readily absorb in these spectral regions, such as amino acids can still be imaged by indirect UV measurements. Here a UVabsorbing buffer is employed as the separation medium and the sample separated by standard techniques. The separated analytes displace the UVabsorbing buffer allowing the transmission of light as the nonUV absorbing analytes pass the detector window. The usual LFII® signal processing algorithms were slightly modified to handle the data processing, but with no loss of repeatability or resolution. Figure 1 shows the separation of 21 common amino acids in less than 11 minutes. 2 LFII® has excellent amino acid analysis (AAA) capability that could be used to measure the uptake of amino acids in a cell culture allowing potential optimisation of the media to the expression system.

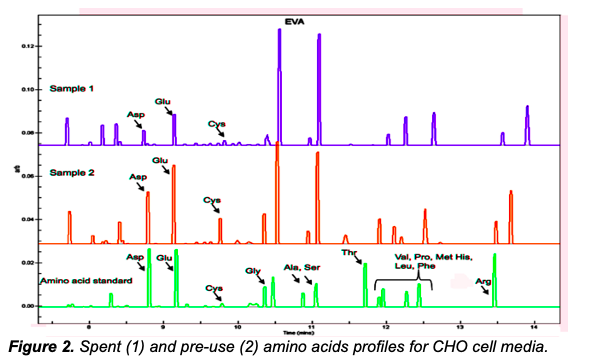

deltaDOT have worked with a major BioPharma to further develop the utility of this application in the bioprocess. Figure 2 shows the difference between spent and fresh media from a CHO cell expression bioreactor during protein production.

The clear and quantifiable differences in the observed amino acid peaks are acquired in less than 15 minutes and this allows the concept of at-line media monitoring. This means that in a meaningful time frame the uptake of specific amino acids can be observed and acted upon in different ways:-

• High use amino acids can be supplemented into the reactor during the process.

• High efficiency uptake profiles could be established for different productions.

• Conditions e.g. Temperature or Oxygen sparging can be altered if uptake appears sub-optimal against pre-determined profiles.

Commercial Applications: The high quality data produced by deltaDOT’s HPCE in the indirect detection can be successfully used as an alternative to existing amino acid analysis techniques in many areas, as follows, to: –

• Monitor the quality of media before use in bioreactor use.

• Adapt and optimise process methodology in rapid time frames

• Assess the incorporation of amino acids used in-process to:-

o monitor the efficiency of protein production

o Allow in-process supplementation of high-use amino acids

• Analyse sugars and contaminants such as lactate using Indirect UV analysis.

Further information For any additional information on our ability to characterise complex samples please contact us on info@deltadot.com